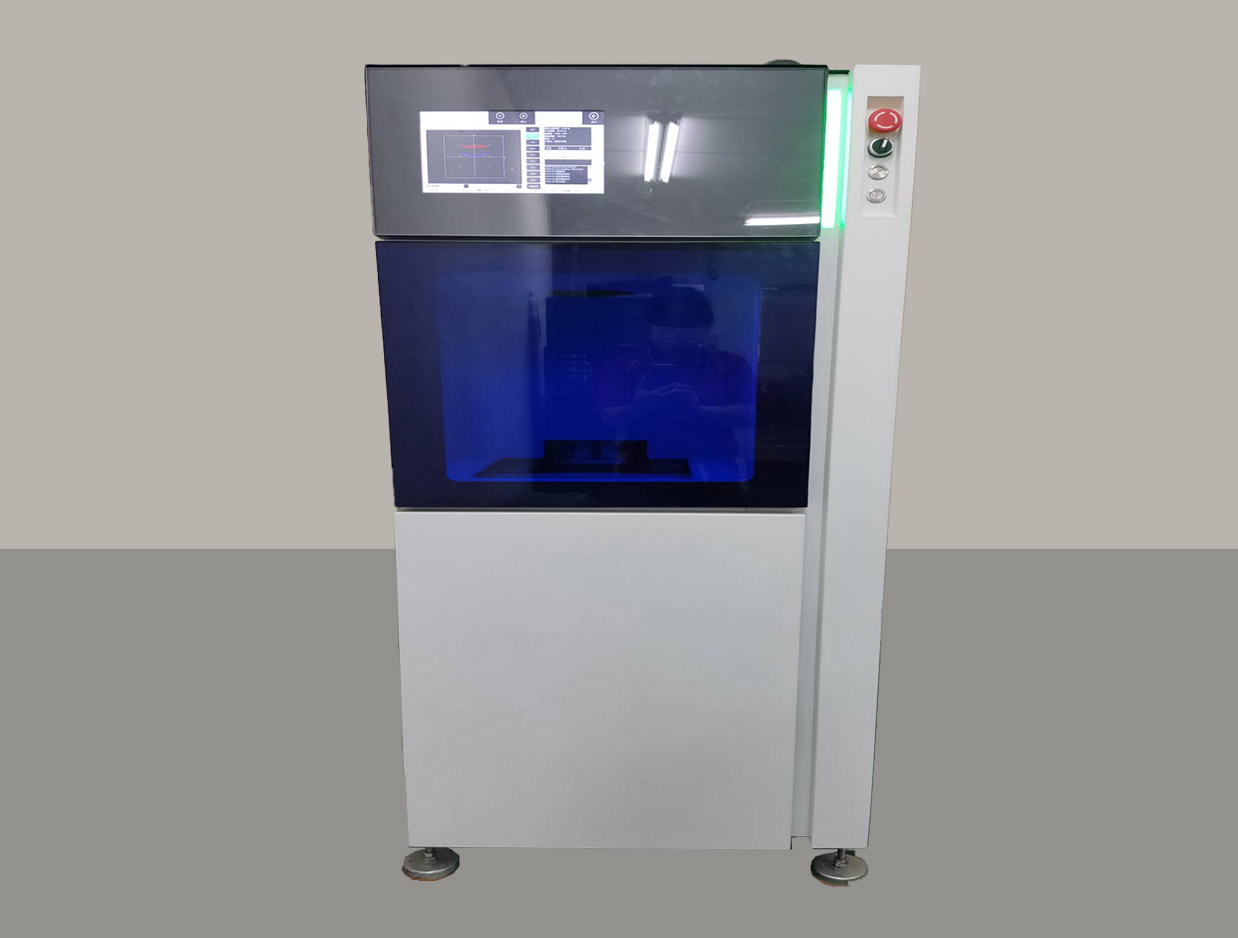

Plastic Injection

We are skilled in handling various materials, such as ABS, PC, PA66, PBT, TPE, PMMA, PC+ABS, and POM, and can provide material recommendations and optimization solutions based on product structure and application.

We are familiar with our clients’ stringent product standards (UL, V0, V1 fire ratings, RoHS, REACH environmental regulations), and can perform DFM assessments and mold flow analyses according to different project requirements to prevent shrinkage, warping and stress problems in advance.

- ISO 9001 Quality Management System

- IATF 16949 Automotive Industry Quality System

- UL Safety Certification System

Our mold and injection engineers are frequently invited to provide clients with product manufacturability consultations and material selection advice, helping them shorten development cycles and improve mass production stability. Internally, we have implemented a full-process traceability system, allowing for tracking from raw material batches and mold codes to production dates.

"From mold development to injection molding, from parts to complete machine assembly, we bring every product from design drawings to reality."

— CHOWSONS Injection Molding Team

This vertical integration capability allows us to truly achieve a "one-stop manufacturing" solution from concept to finished product.