SMT Production

SMT Production

DFM design optimization

Our engineering team has extensive experience in identifying potential process

risks during the design phase, helping

customers avoid subsequent production problems.

Prototype to Mass Production

We are flexible in accepting orders and can meet your needs, whether it is a

small batch trial production or a large

batch production.

Turnkey to Consigned, Flexible for Every Need

We can manage the entire process, from parts procurement, manufacturing,

assembly to testing, and deliver complete

products that are ready for immediate use. Alternatively, you can provide the materials

according to your needs, and we

will focus on high-quality production.

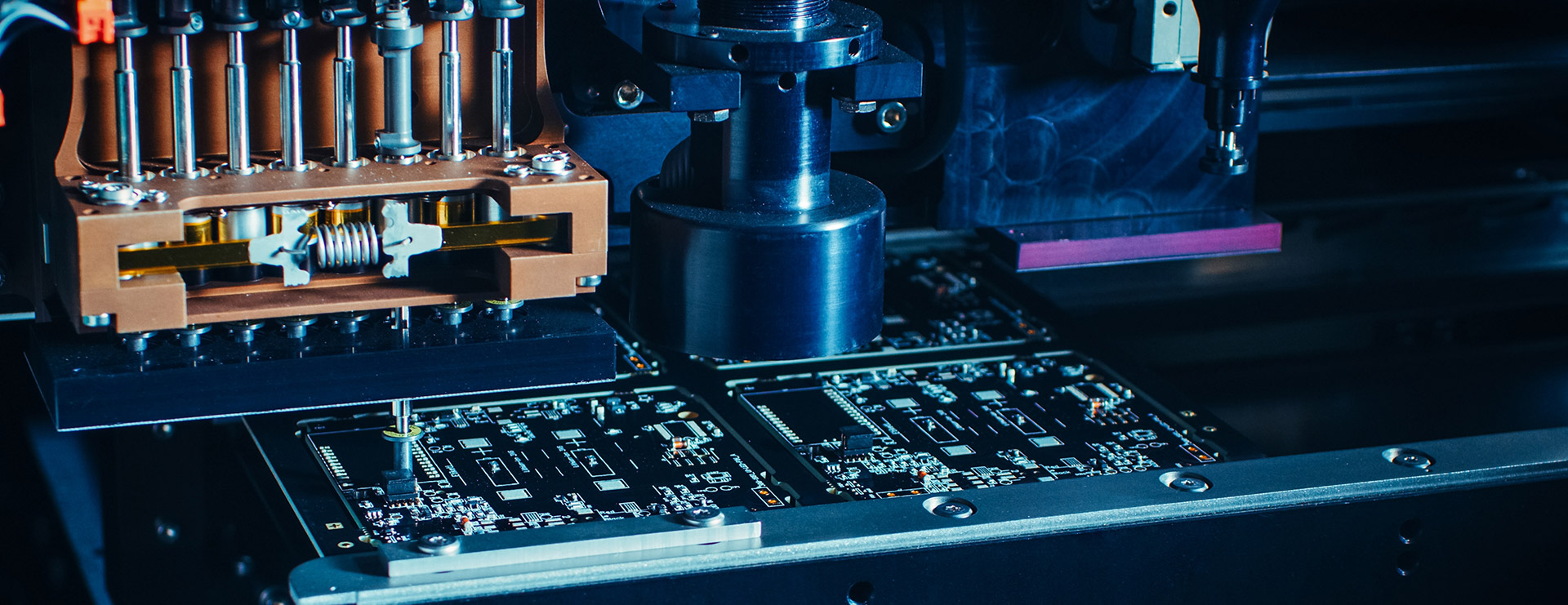

Full-Scope SMT Production

01

Material and component inspection

All materials and components undergo strict quality inspections upon arrival,

including size, pin/pad inspection, and

inventory tracking

02

Solder paste printing

High-precision solder stencil and solder paste supply systems are used to

ensure solder paste thickness and coating

uniformity, avoiding bridging or insufficient solder joints

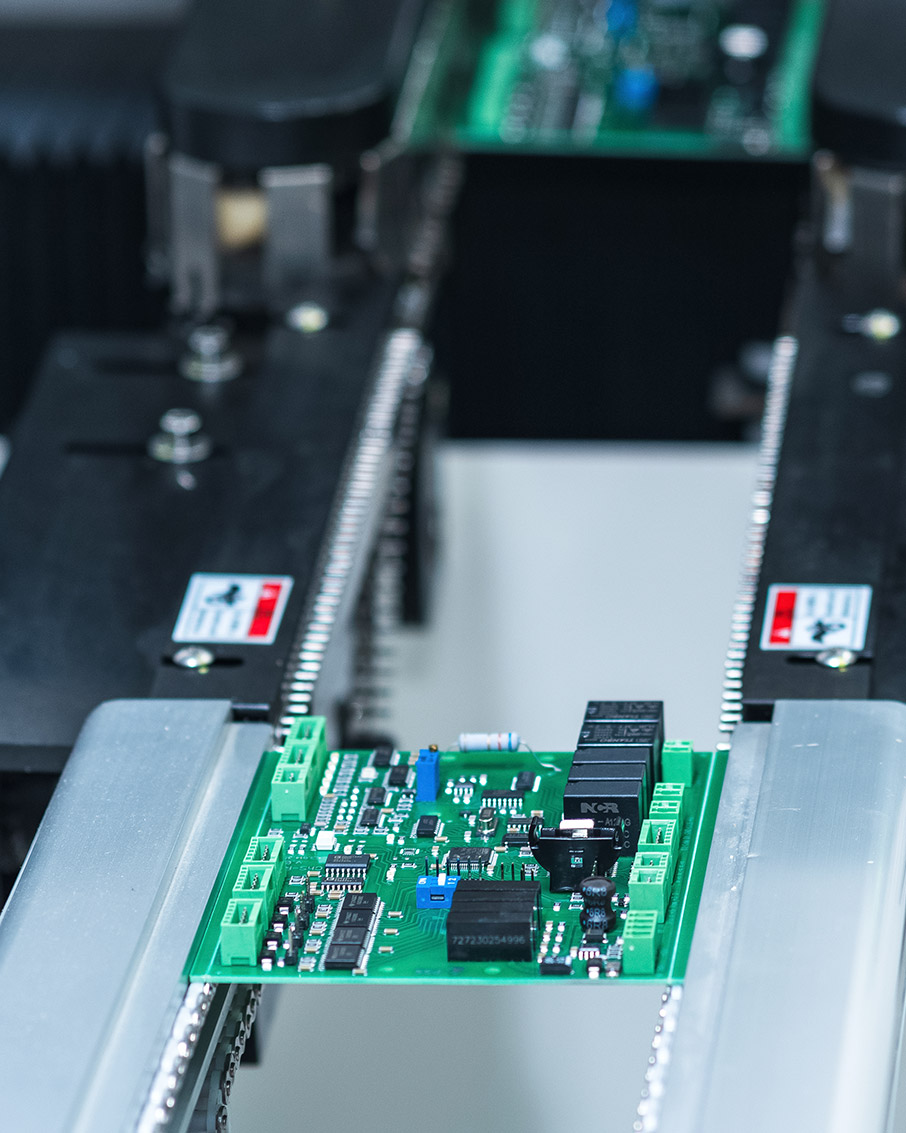

03

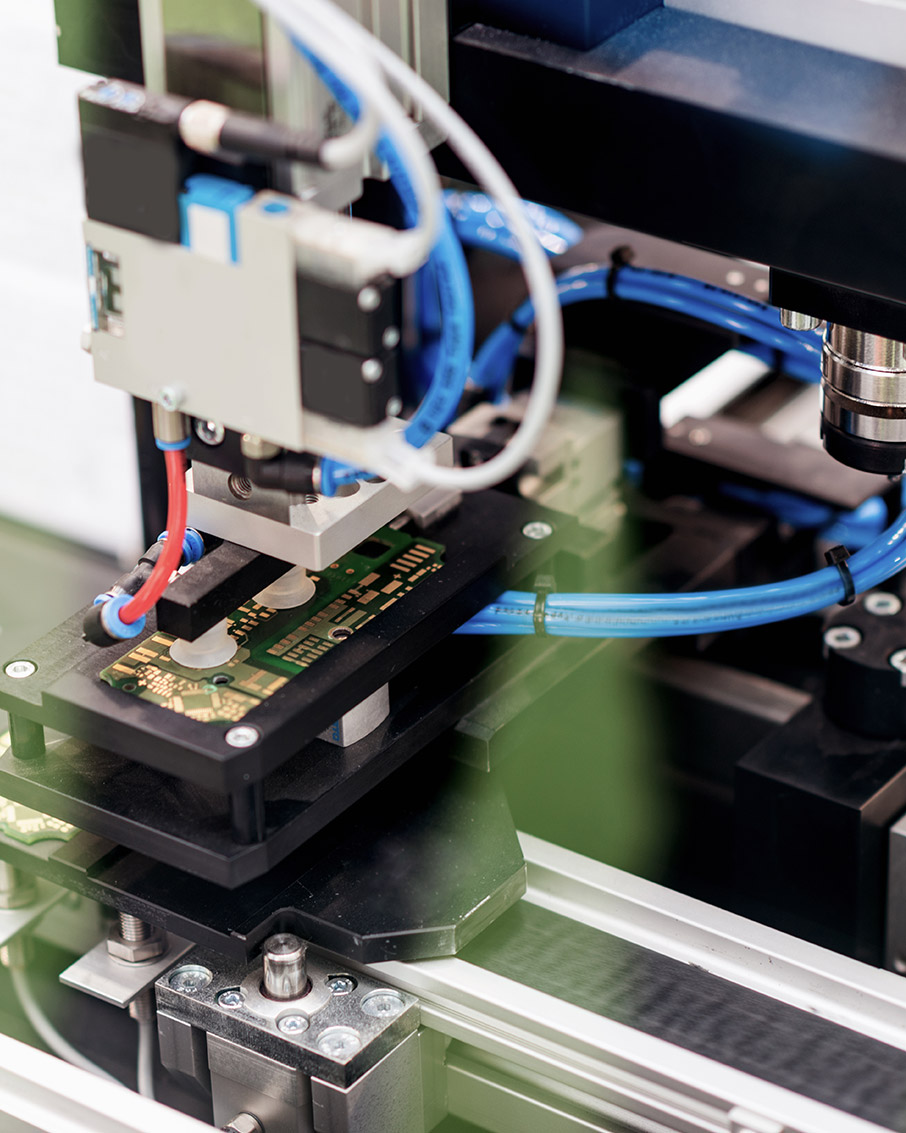

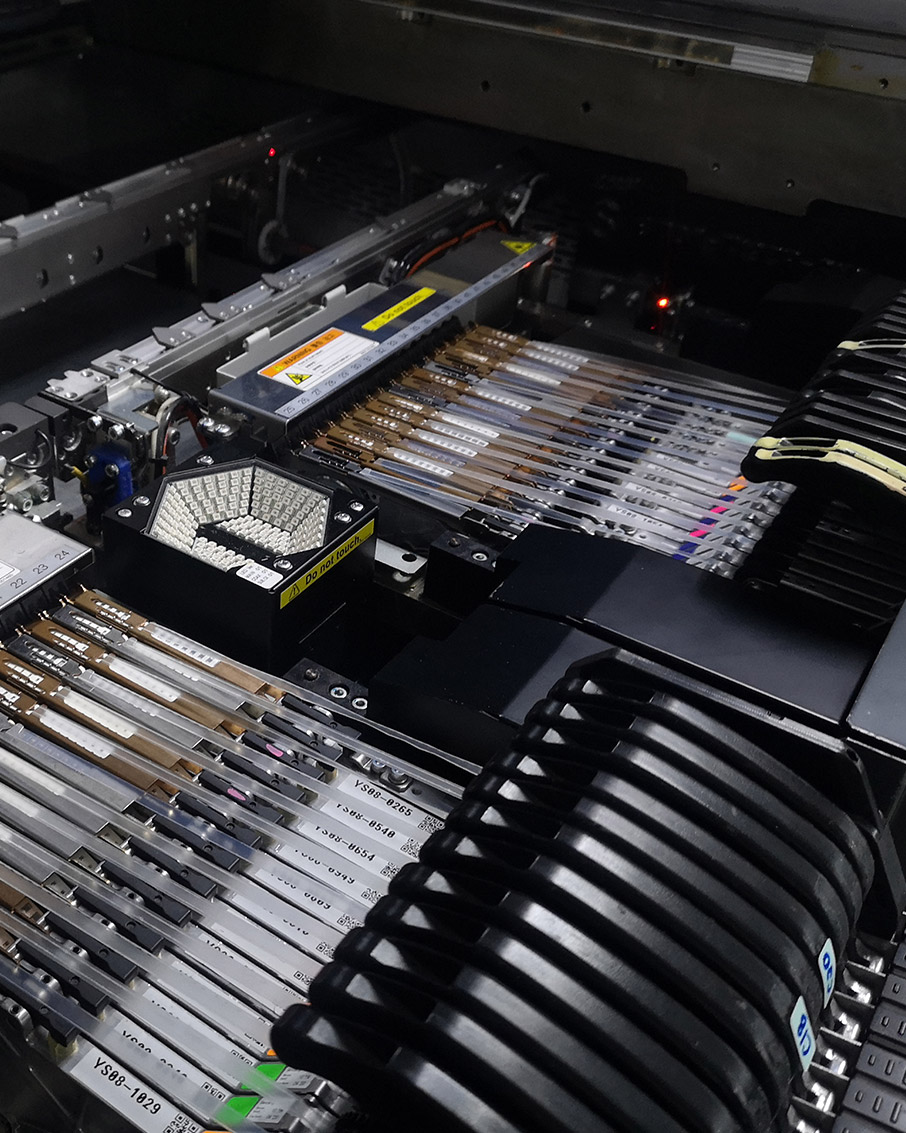

Mounted components

Using multiple high-speed automatic placement machines, we can mount fine-pitch

BGA, QFN, 0201 and other tiny packages

04

Reflow soldering

Precisely control the temperature curve to ensure that all components achieve

the best welding quality and reduce

problems such as cold welding and biased welding

05

DIP Assembly

In addition to high-efficiency SMT processes, CHOWSONS is equipped with

multiple DIP production lines to meet the needs

of power modules, industrial controllers, and communication devices. For critical components

such as capacitors and

large transformers, the DIP process ensures unmatched stability and reliability.

Why Choose Us

bug

fix

Process Diversity

Capable of handling double-sided SMT, hybrid technology (SMT + THP), and

high-density interconnect (HDI) boards for a

wide range of applications.

One-Stop Service

With in-house mold making, injection molding, and assembly facilities, we

deliver complete product assembly while

reducing communication costs.

Flexible Manufacturing

From small-batch pilot runs to large-scale mass production, we support both

SMEs and global brands with equal

efficiency.

Robust Supplier Management

for Assured Quality

Trusted & Certified Partners

Only suppliers with internationally recognized certifications such as ISO 9001

and IATF 16949 are qualified. On-site

audits validate their production capabilities, quality controls, and management integrity.

Performance-Driven Monitoring

Through KPIs such as PPM, acceptance rate, and on-time delivery, we

continuously evaluate supplier performance to secure

reliability and drive ongoing improvement.

Zero-Compromise Sample Validation

Before mass production, rigorous First Article Inspection (FAI) and PPAP

approval ensure every sample meets exact design

specifications, preventing risks at scale.

A Rigorous Journey of

Quality Assurance

01

AI+AOI

Detects placement issues such as misalignment, tombstoning, missing, or

duplicate components.

02

X-Ray

Provides in-depth analysis of hidden solder joints for BGA, QFN, and other

complex packages.

03

MES

Integrates with the Manufacturing Execution System to enable immediate tracking

and resolution of defects.

Reflow Process Control

01

Thermal Profiling

Ensures temperature zone curves comply with IPC standards.

02

Temperature Curve Calibration

Establishes tolerance control with green, yellow, and red zones

03

FMEA Risk Assessment

Applies Failure Mode and Effects Analysis to evaluate risks from temperature anomalies.

Igniting a New Era of B2B

Partnership

bug fix

Key to Enhancing Competitiveness

One-stop services are a vital strategic tool for modern enterprises to boost

market competitiveness

Comprehensive Efficiency Optimization

Streamlining operations to reduce overall costs while improving product quality

and delivery stability.

Creating the Future Together

Building long-term strategic alliances with professional partners to shape a

mutually beneficial and win-win business

future.

Functional Testing &

Verification

bugfix

ICT

Checks basic electrical characteristics such as open circuits, short circuits,

and resistance deviations.

FCT

Simulates real-world application environments to validate overall product

performance.

Programming & Verification

Ensures consistency between hardware and software in critical components and

verifies program accuracy.

Pro Tips: We work closely with multiple professional test fixture partners to

provide customized fixture design and

manufacturing solutions, helping enhance product testing efficiency and ensure quality

consistency.