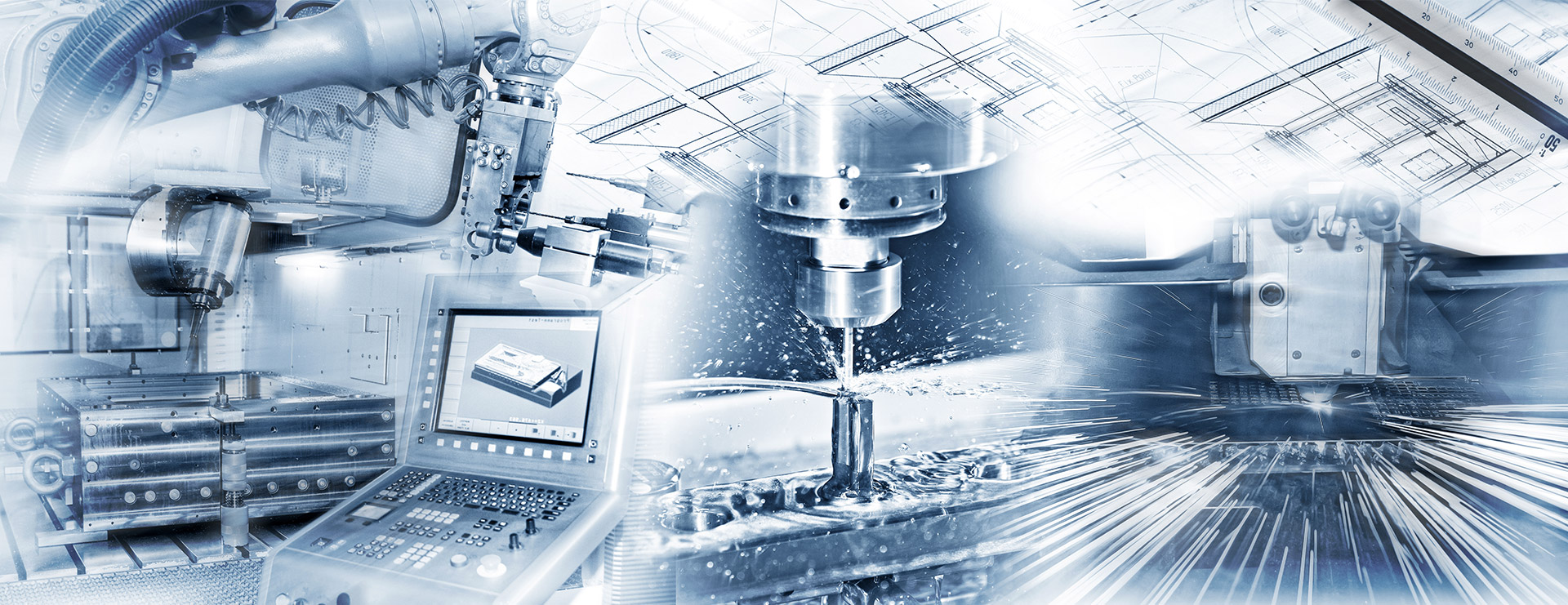

Mold Design &Tooling

Plastic Mold manufacturing

A Complete Journey from Concept to Product

Plastic mold development is a sophisticated engineering journey — each step shaping the

quality, cost, and efficiency of

the final product.

Transforming a concept into mass production demands the integration of materials

science, mechanical engineering, and

process control expertise.

Join us in exploring this vital manufacturing journey — turning your ideas into premium

plastic products.

Crafting excellence, driving the future of manufacturing innovation.

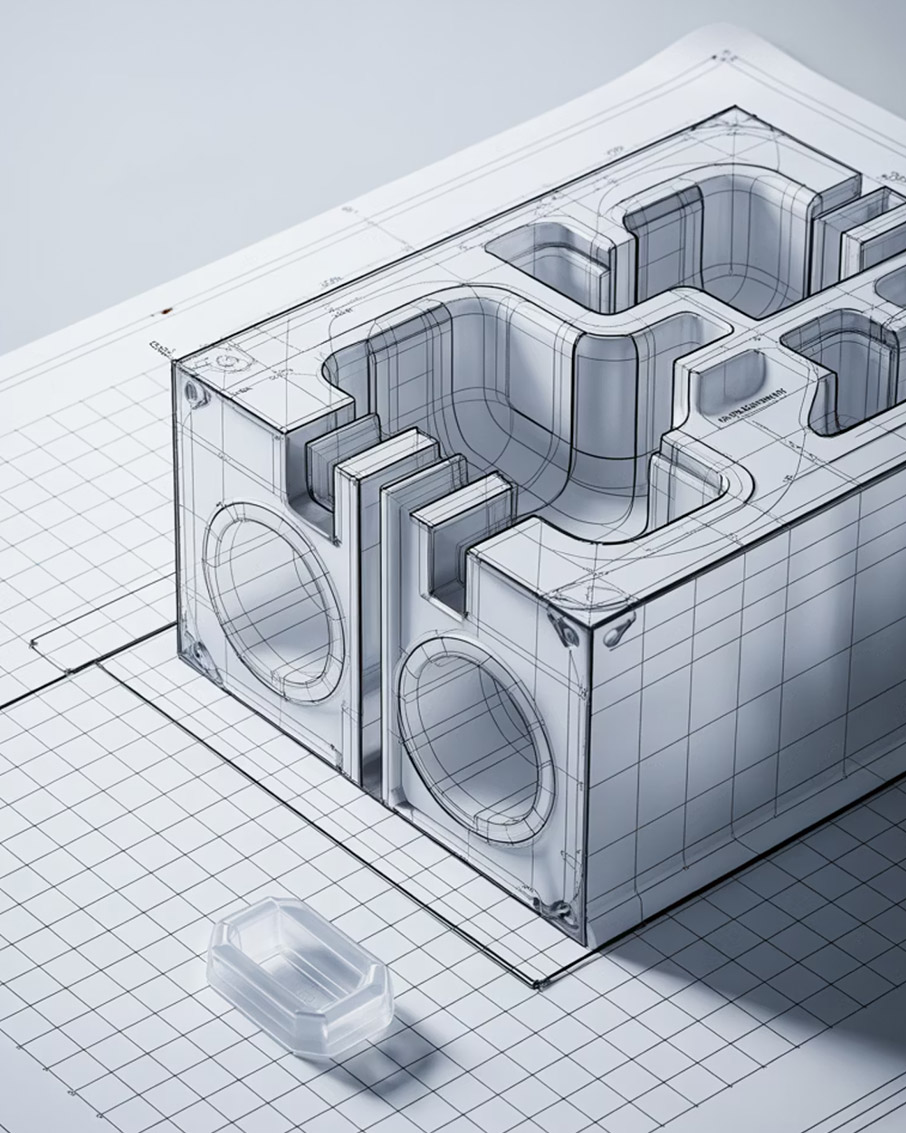

Step 1: Confirm drawings and requirements

01-Drawing Completeness Check

Verify whether the files provided by the customer are complete (including 2D dimensions,

3D models, material

specifications, tolerances, and surface treatment requirements).

02-Aligning with Customer Requirements

Verify product functions, appearance specifications, and usage environment (e.g., heat

resistance, impact resistance, UV

resistance, etc.).

03-Material Selection

Different plastics or metals have a significant impact on mold design, processing

methods, and overall cost.

Step 2: Design for Manufacturability

Structural feasibility review

- Check for undercuts that require sliders or lifters.

- Ensure uniform wall thickness to avoid shrinkage or warpage.

- Verify sufficient draft angle to ensure smooth ejection.

Check points

- Parting Line Design: Ensure the product’s appearance is not affected.

- Gate Location: Critical for flow balance, weld lines, and product appearance.

- Mold Flow Analysis: Simulates plastic flow, filling pressure, and cooling time to identify potential issues early.

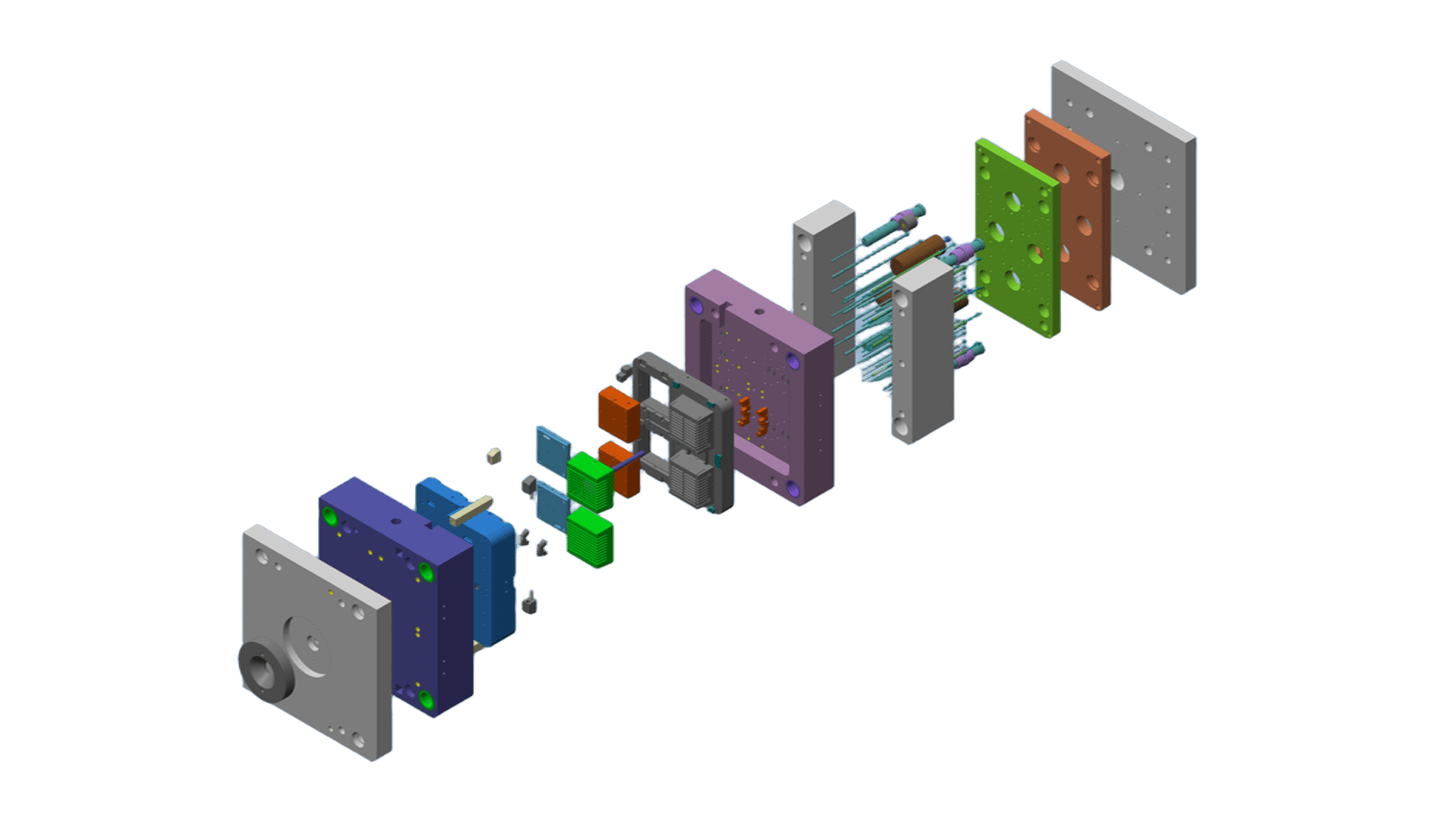

Precision Mold Structure Design

- Optimizing Cavity Design

- Ejection Mechanisms (Pin, Block )

- Cooling System Design

Steel Material Selection

Choose steel grades based on product requirements such as lifespan, precision, and

material properties. Different steels

offer varying performance characteristics.

Cost and Lead Time Evaluation

List mold costs, tooling cycle, and trial mold (T0/T1) schedules.

Pro Tip: Detailed

pre-planning is the foundation of mold development success — every step matters and must be

meticulously evaluated.

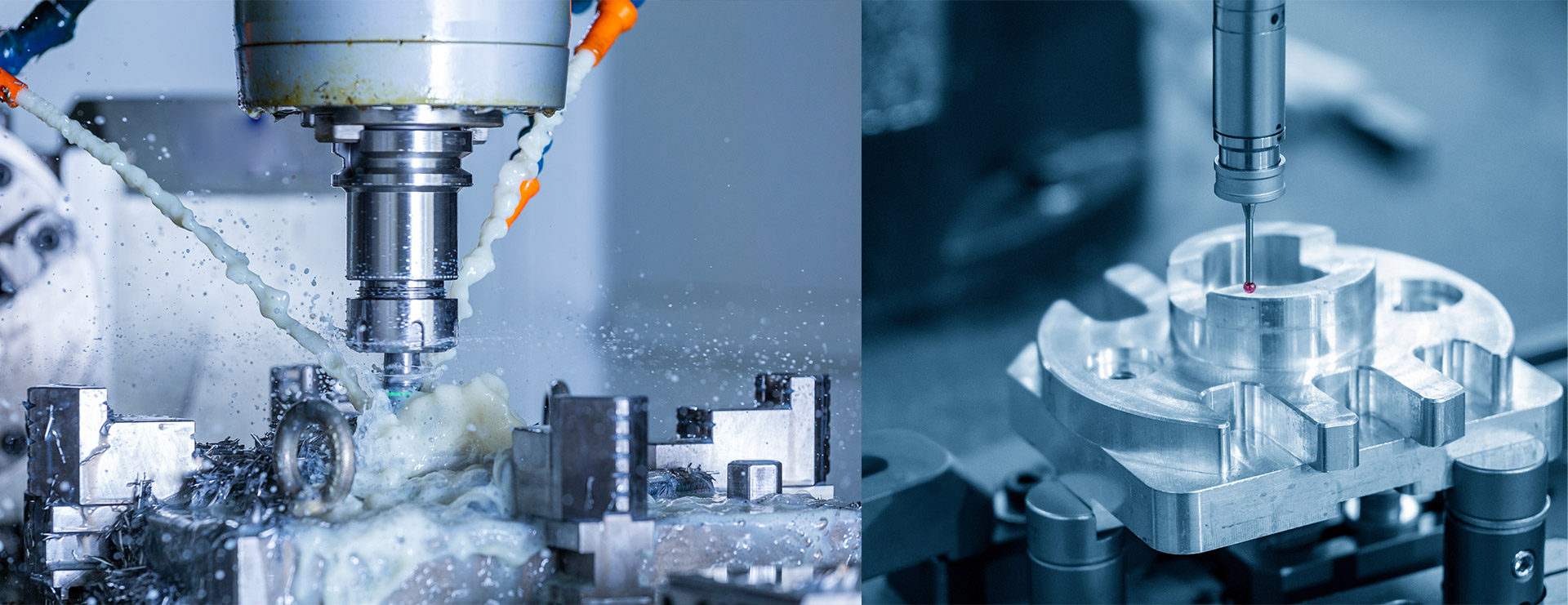

Step 3:Precision Mold

Design Engineering

Structural Design

Key factors such as injection flow, cooling system, and ejection mechanism are

taken

into consideration to ensure stable

and efficient mold operation.

Precision Control

Utilizing CAD/CAM technology, we accurately calculate mold dimensions to ensure

product

tolerances meet specification

requirements.

Durability Design

Optimizing mold structure to extend life cycle, reduce maintenance costs, and

improve

production efficiency

Step 4: Mold Assembly and Quality Testing

Precision Assembly

Assemble the machined mold components with high precision to ensure perfect fit of all

parts

Trial Molding Verification

Conduct comprehensive mold testing to verify whether injection parameters and product

quality meet design requirements

Precision Adjustment

Make necessary adjustments based on test results to ensure the mold reaches its optimal

production condition

Total Quality Control

CHOWSONS has invested in advanced technologies for mold development, ensuring

strict control from design and prototyping

to mass production, so that every product meets both precision and efficiency

requirements.

Within its quality system, APQP (Advanced Product Quality Planning), PPAP (Production Part Approval Process), SPC (Statistical Process Control), and 8D (Eight Disciplines Problem Solving) are implemented to ensure that issues can be quickly prevented, tracked, and resolved.

Within its quality system, APQP (Advanced Product Quality Planning), PPAP (Production Part Approval Process), SPC (Statistical Process Control), and 8D (Eight Disciplines Problem Solving) are implemented to ensure that issues can be quickly prevented, tracked, and resolved.

01

APQP

Quality planning and risk assessment during the early stages of product development.

02

PPAP

A rigorous review and approval process for production parts.

03

SPC

Real-time monitoring and analysis of process data

04

8D

A systematic mechanism for problem tracking and continuous improvement.

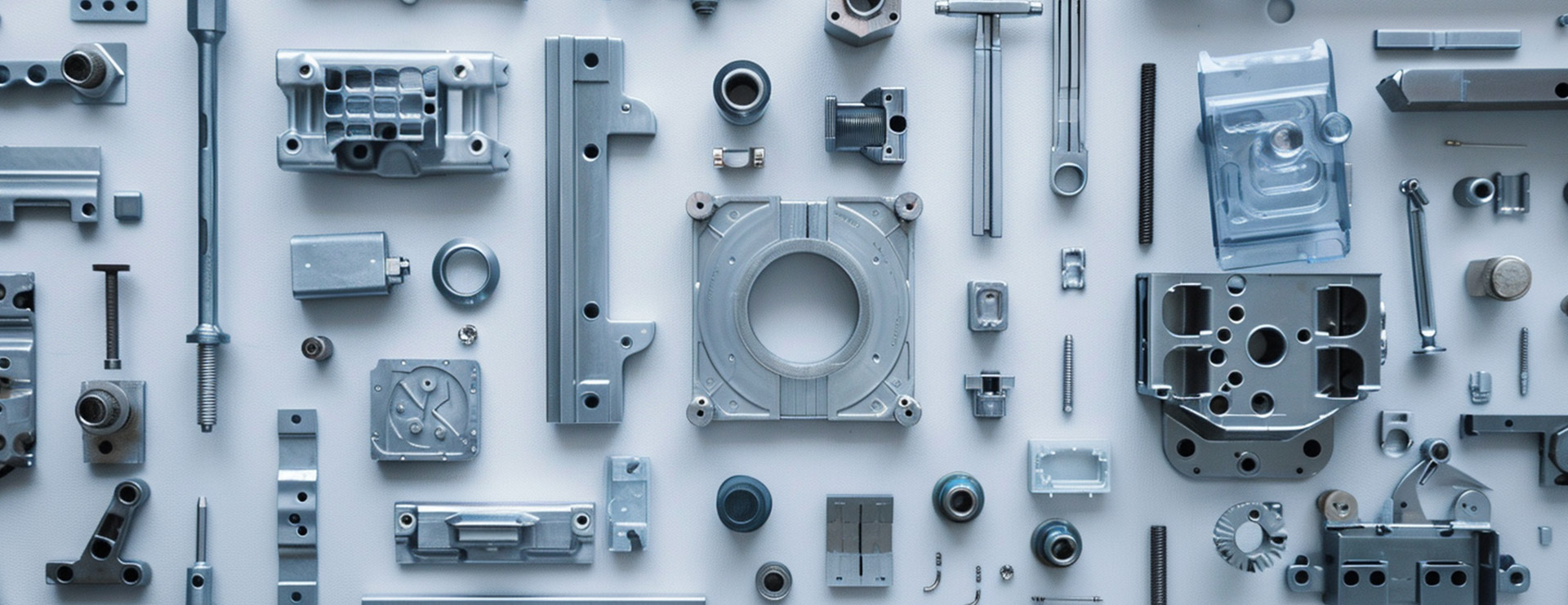

Core Competencies

bug

fix

Precision Assembly

With 40 years of expertise in plastic manufacturing, our mold structure design not only

meets customer requirements for

appearance and dimensional tolerances but also emphasizes ease of mold maintenance

Injection Molding Expertise

We possess comprehensive experience in plastic injection molding, optimizing ejection

structures and cooling system

installation methods with a focus on production efficiency

One Stop Service

From mold design and fabrication to injection mass production, we provide a single-window

solution that reduces

communication costs and management complexity