Engineered for Variety

When trust serves as the foundation, collaboration stands on solid ground. Based on confidence in our mutual client, this American company quickly entrusted us with two dashboard instrument models for evaluation, testing whether CHOWSONS possessed the manufacturing expertise they required. This trust became the perfect stage for demonstrating our professional capabilities.

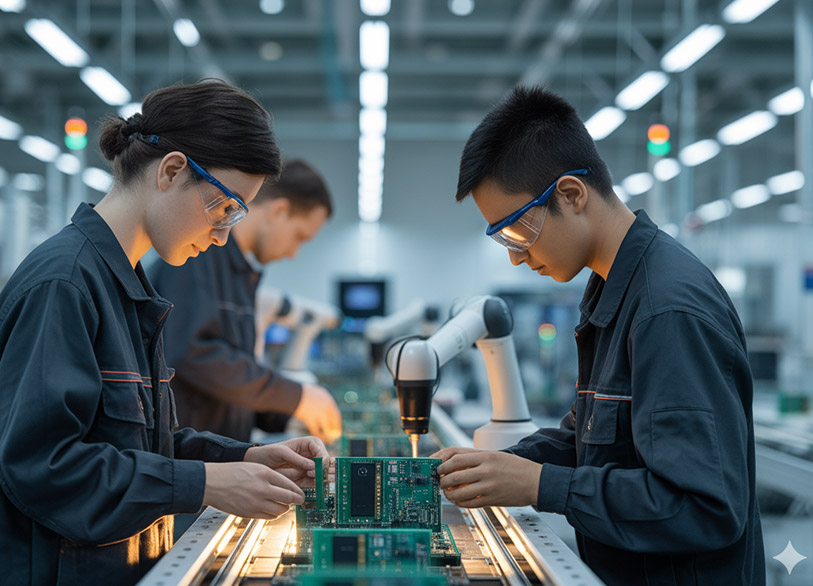

Leveraging years of accumulated SMT expertise, we precisely controlled electronic component soldering quality and circuit board reliability. Simultaneously, in injection mold design, our engineering team could rapidly create models and refinements, ensuring perfect alignment between product appearance and functionality. This comprehensive technical integration capability enabled us to deliver competitive quotations quickly, establishing a solid foundation for subsequent collaboration.

Our engineers and quality management personnel collaborated closely, employing PDCA cycles (Plan-Do-Check-Act) to systematically overcome technical obstacles. For instance, when handling Custom Cable Assembly, we designed specialized cable structures for different signal requirements, ensuring transmission stability. In Precision Metal Parts Manufacturing, we introduced high-precision stamping equipment, controlling tolerances within 0.05mm. This commitment to quality demonstrated our professionalism and determination to clients.

This "one-stop service" capability represents CHOWSONS' core competitive advantage in the high mix low volume manufacturing sector. We not only possess technical strengths in SMT electronic assembly but also integrate diverse processes including mechanical processing, mold development, and metal forming. For clients, rather than distributing orders among multiple suppliers, partnering with a single trusted ally reduces communication costs while enhancing product consistency and delivery stability.

Today, this American auto tuning company has become a crucial long-term partner for CHOWSONS. From the initial two instrument models to the stable supply of dozens of product types now, this collaboration demonstrates how trust transforms into business value and proves how professional expertise earns market respect.

Whether your products require high mix low volume or large-scale production, CHOWSONS offers customized manufacturing services. Contact us today and let our professionalism and passion make us your most trusted manufacturing partner!

Q1: What advantages does CHOWSONS have in SMT technology?

CHOWSONS possesses extensive SMT (Surface Mount Technology) experience with advanced automated production equipment capable of handling high-density circuit board assembly, precision soldering, and rigorous quality inspection. We particularly excel in high mix low volume manufacturing models, rapidly responding to clients’ diverse requirements.

Q2: What is high mix low volume manufacturing, and how does CHOWSONS achieve it?

Q3: What customization services does CHOWSONS provide?

We offer comprehensive customized manufacturing services including: Custom Cable Assembly, injection mold design and manufacturing, Precision Metal Parts Manufacturing, PCBA circuit board assembly, plus product assembly and testing—a complete one-stop solution.

Q4: How long does it take from product evaluation to mass production?

Timelines depend on product complexity, but CHOWSONS is known for rapid response. Generally, evaluation and quotation for simpler products can be completed within 1-2 weeks, with trial production requiring approximately 4-8 weeks. We maintain close communication with clients to ensure each phase meets expected timelines.

Q5: How does CHOWSONS ensure product quality?

We employ ISO quality management systems with strict standards from raw material inspection through process control to finished product testing. Every product undergoes multiple quality inspection checkpoints, including dimensional measurement, functional testing, and reliability verification, ensuring delivered products meet the highest standards.